We are convinced that both in the area of classic stationary energy conversion (gas or coal-fired power plants, etc.) and in the area of mobile drive systems (in particular electro mobility via range extension systems) the continuing trend towards small, decentralized systems will be reinforced. In both main areas we see permanent fields of application and remarkable market volumes for systems and development services of Euro-K GmbH.

PERSPECTIVES OF THE EURO-K

On the one hand, decentralized, stationary energy conversion is characterized by the classic area of Power-Heat -Cooling-Coupling which mostly based on internal combustion systems for liquid and gaseous fuels; on the other hand, energy sources that have so far been of secondary priority, usually only thermally utilized, the so-called hidden fuels, such as solids (wood, industrial cutting residues, biomass, etc.) and weak or mixed gases (flare gases, ultra-weak gases, landfill gas, etc.) will play an increasingly crucial role in utility-independent on-site electrical energy conversion.

Because of the wide range of different system solutions in the market for Power-Heat -Cooling-Coupling via internal combustion plants (gas and diesel engines, micro gas turbines, fuel cells, Stirling, etc.), which go far beyond turbine technology, we assume that the healthy competition that already exists will continue unavoidable as for the increasing electrical efficiencies in the future.

In this respect, existing niche markets in the area of residual material utilization will play an appreciable role in the future energy mix. By combining a variety of advantages, such as self-sufficient energy conversion on site by the consumer, avoidance of residual material disposal costs with simultaneous highly effective availability of the fuel, avoidance of energy procurement costs and minimization of necessary logistics efforts, profound economic and ecological value will be achieved in the area of small and micro energy converters.

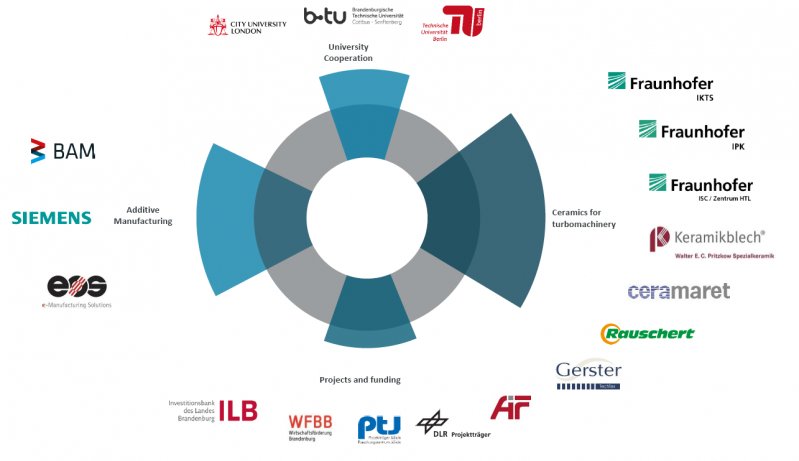

In order to be able to offer our customers the best solutions as well in the future, we are constantly improving the basic technology and applying it into current products, so that they could meet the changing requirements. On the technology side, we are pushing ahead with component solutions in particular, such as internally cooled SLM-based radial turbines, compact lancet tube recuperators and ceramic solutions for the high-temperature range. These developments will enable an improvement in electrical efficiency in the single-digit percentage range within the next few years (target value approx. 38 %el for the < 100 kWel power class).

Thanks to the modular structure of the Euro-K system solutions, these improvements can be integrated into the turbomachinery regardless of power class and application, and therefore achieve extensive technical benefits. Furthermore, these advances, especially the high-temperature components, enable the transformation from two individual basic technologies into the combination of turbine and high-temperature fuel cell (MGT SOFC). The implementation of this system will be processed by Euro-K GmbH in cooperation with the scientific and technical partners of BTU Cottbus – Senftenberg within the next decade.

The technically achievable efficiencies >> 60 %el with simultaneous availability of a wide fuel range and compact design realizes widespread applications and significant economic and ecological advantages.

Euro-K GmbH has set the goal to make important contributions to advanced energy conversion in the 21st century through the development of the MGT-SOFC and to meet the challenges both at present and in the future with innovative systems “Made in Germany”.

» The CHP plant for decentralized energy! ClinX generate green power and heat from biomass or residual materials!

» Consulting on decarbonization & pyrolysis CHP: Green electricity & biochar from one energy plant!

EURO-K | PURE GERMAN ENGINEERING

Tel.: +49 (0)355 8695 9890

Mail: service [at] euro-k.de