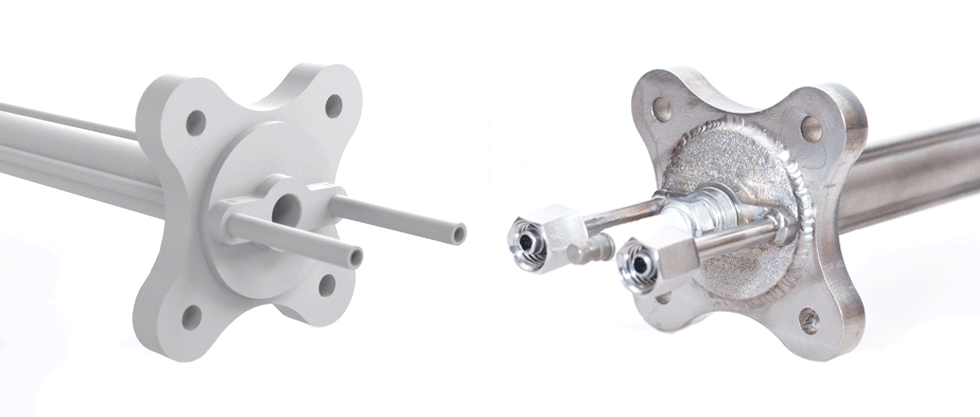

Euro-K supports customers in the areas of concept development, process analysis and project planning for a variety of different product solutions. As an extension of this, we are also able to design both individual components and complete systems according to specific customer requirements and in compliance with applicable legal requirements such as the Pressure Vessel Directive EC97/23/EC and then present them as ready for production. In this context, we also offer concepts for instrumentation and data acquisition tailored to customer systems. For new generation of design solutions, we use the advantages of additive manufacturing. With the help of these manufacturing processes, the previously unattainable design solutions and thus further weight and cost reductions can be realized.

SERVICES OF THE EURO-K

Euro-K uses FEM simulation to evaluate the integrity of the design even before the first prototype and is thus able to reduce the number of cost-intensive physical models to minimum.

Weak points were identified by our engineers at the early stage, which results in the reduction of development time and the increase of product quality. Due to its reliability and informative value, the FE method is an efficient tool in product development and is used intensively by us in all development phases. In addition, we use the FE method as a basis for optimization procedures for weight reduction and robust component behavior.

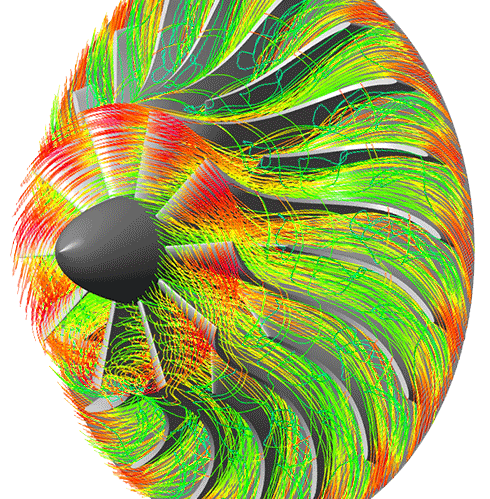

With the usage CFD numerical flow simulation, we design our turbomachinery and other fluid-inducing parts regarding the required process parameters in a time-effective and cost-efficient way. By using suitable solvers, the operating behavior can be estimated at an early stage and possible flow instabilities can therefore be detected. In addition to flow control, we are also able to visualize combustion reactions and carry out corresponding optimization processes. The machines designed in this way are recognized by excellent performance values and are more than sufficient to meet the high demands of our customers.

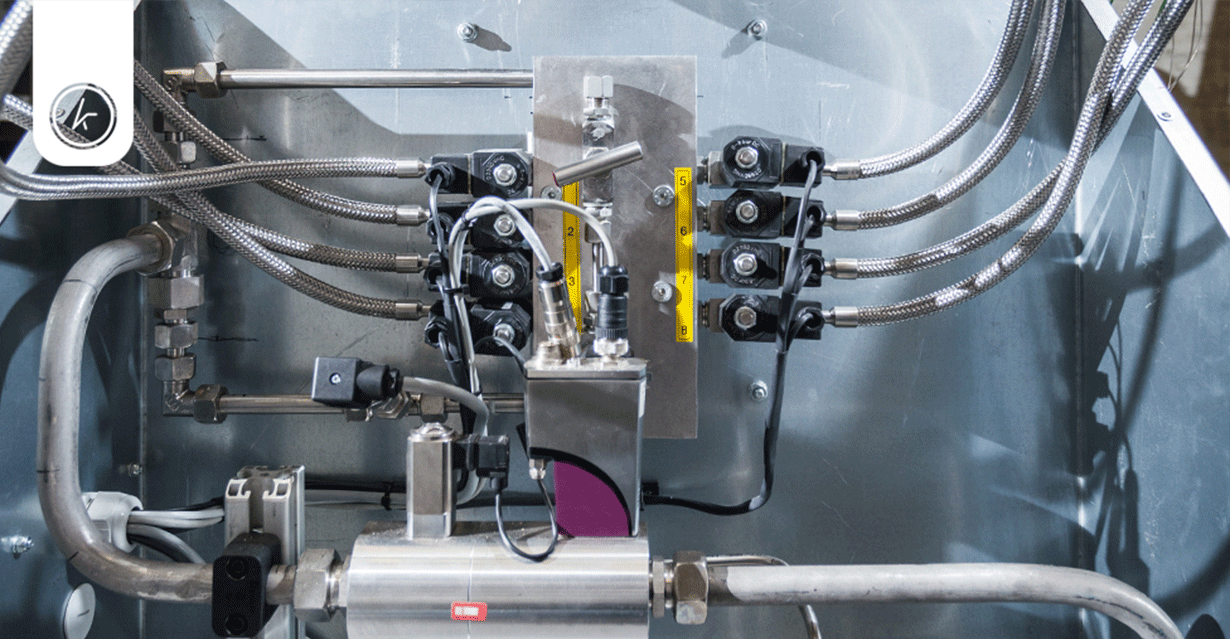

In order to validate our design results, Euro-K has the most modern test benches available for specific projects in order to be able to efficiently and reliably validate both components and results from the simulation processes in real tests. This covers the spectrum from individual component test benches to test benches for complete systems. The test benches are modularly designed from the outset so that a wide variety of test configurations can be realized. Here identifies 35 kW micro gas turbine test bench itself as an example.

All offers are focused on the implementation of energy technology projects and the generation of non-market solutions. The project team uses its years of experience in the field of gas turbine technology and combustion systems to provide novel solutions for energy conversion systems, which are especially adapted to fit the existing boundary conditions. Innovative tools, such as rapid prototyping technology, are used to optimize the development process. At last, Euro-K GmbH also supports the entire patent acquisition process in the partner network as desired. Below you will find an overview of our consulting portfolio:

- Consulting services (plant engineering, fuel conversion)

- Project planning and support

- Process analysis, planning and system integration

- Design services for development projects

- Rapid prototyping via PLA printer

- Patent preparation and support

EURO-K | PURE GERMAN ENGINEERING

Tel.: +49 (0)355 8695 9890

Mail: service [at] euro-k.de